Doors and Windows

INNOVATIVE TECHNOLOGIES

Fametec has developed technologies that allows us to cover all production sectors to facilitate the doors production in every single department, after the pressing phase, and we have implemented single units, working islands or in-line machinery such as:

Machining centers and calibration and milling lines;

Processing and accessory installation machinery with integrated vision systems;

Application unit seals and special clamps;

Anthropomorphic robots, connection automation, loading and unloading systems.

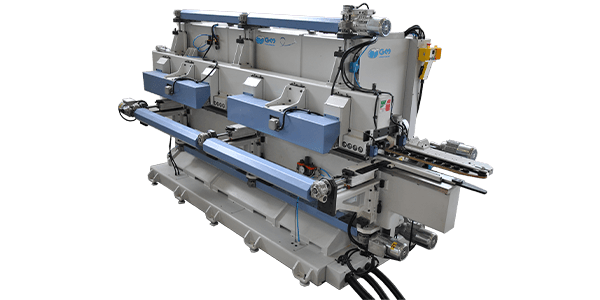

HARDWARE FITTING MACHINE

We have developed a technology that allows us to cover all production sectors to facilitate the doors production in every single department, after the pressing phase. Specifically, we have implemented single units, working islands or in-line machinery for the installation of accessories such as hinges, striker plates and locks using robotic manipulators and integrated vision systems, to ensure maximum production flexibility.

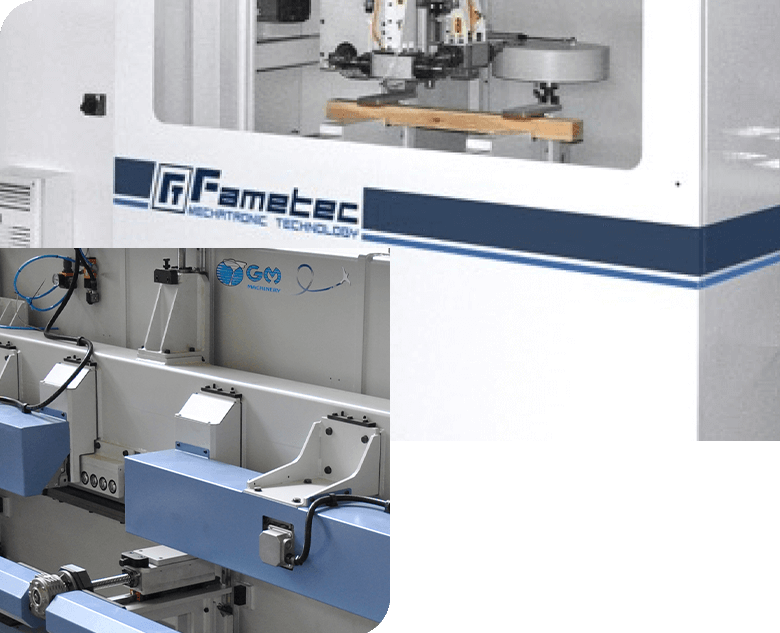

MACHINING CENTRES

Identifying the ideal solution for every production need becomes the key to success, both for the machine manufacturer and product producer, in this case the window or door frame.

This is why we are constantly committed in listening to our customers, confronting them and dedicating the right resources to a constant research of innovative technologies, adapted to modern production needs, in continuous and rapid evolution

At FAMETEC-GM we try to translate these design dynamics into all our projects, from simple corner systems to more complex machining centres and special machinery.